Kartek Off-Road 1-3/4" Lower King Pin Sleeve For Our 6-1/4" Trophy Truck Or Class 1 Billet Clevis

California Prop 65 Warning: This item may cause cancer or reproductive harm. For more info visit p65warnings.ca.gov

California Prop 65 Warning: This item may cause cancer or reproductive harm. For more info visit p65warnings.ca.gov

Description

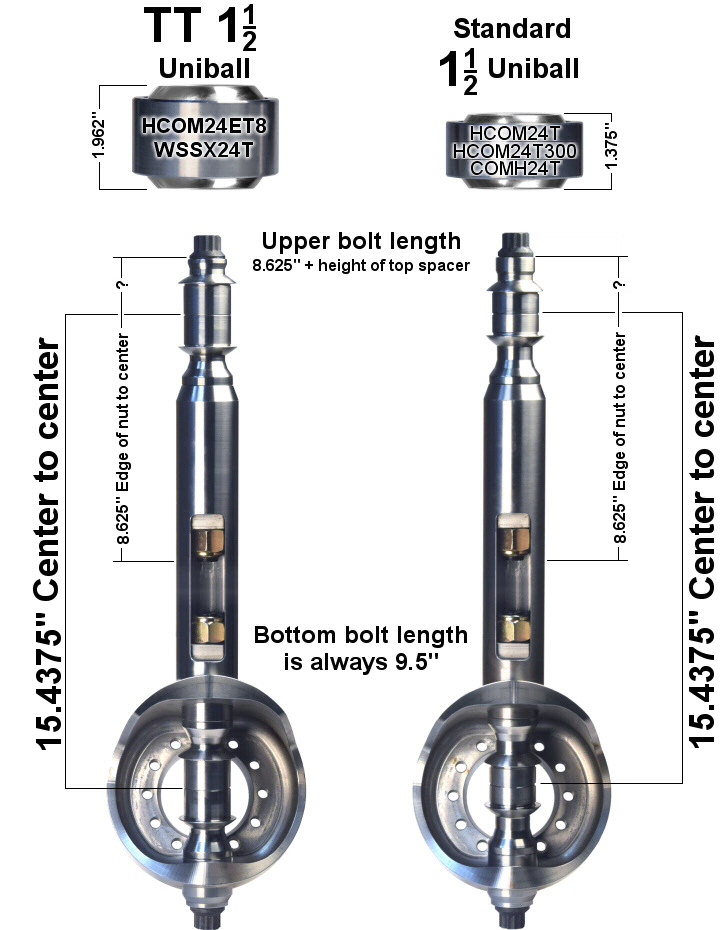

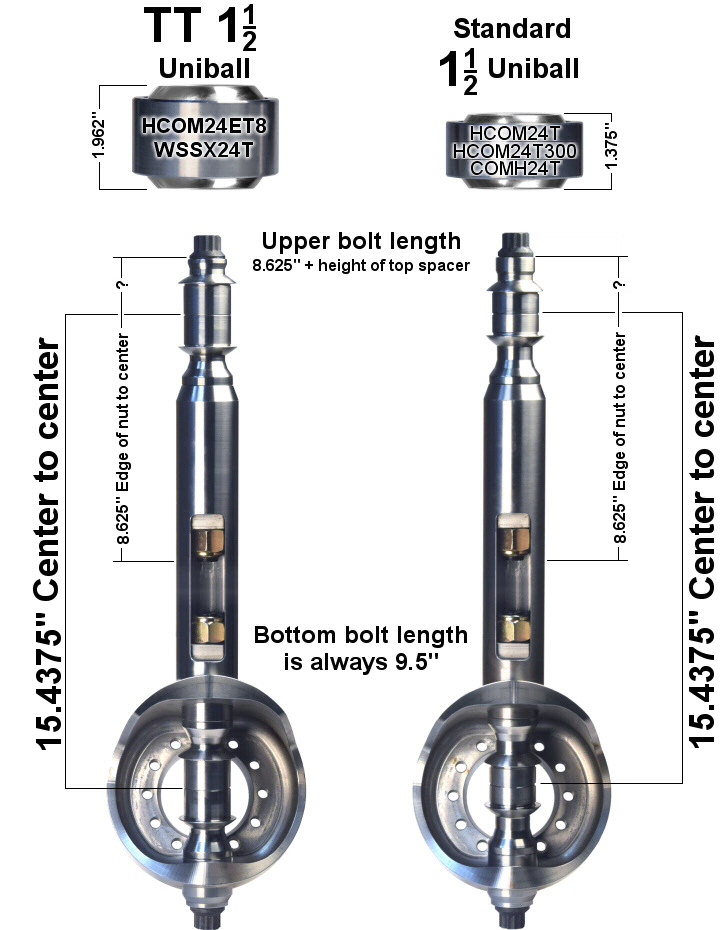

Everything for the billet uprights are sold á la carte. You'll need to consider degree of inclination, upper bolt length (usually 9-1/2" or 10-1/2" on this setup, but depends which very top misalignment you decide to run) and if you want to run standard 1-3/8" tall uniballs or the taller TT uniballs that are 1.962" tall.

The center to center dimension doesn't change, regardless of which uniballs you decide to run, because we've already compensated for that with the height of the misalignments that we sell. You can cut the king pin down if you need a shorter center to center but you'll have to compensate with your bolt length and re-step the kingpin on a lathe. We sell two different upper king pins for this setup. 10-1/4" upper pin makes 14-7/16" on center and 11-1/4" upper pin makes 15-7/16" on center.

The top of the kingpin is stepped and requires a certain misalignment that indexes onto that step. Part number HMA15034KTKWS for the standard uniball or part number TTHMA15034PRM for the taller TT uniball.

You will have to make your own caliper brackets. We do not offer those. You could use our 5.9" clevis gusset kit part number 59SPGK, but you'll have to trim it up quite a bit to fit this larger diameter clevis and kingpin.

You will have to make your own caliper brackets. We do not offer those. You could use our 5.9" clevis gusset kit part number 59SPGK, but you'll have to trim it up quite a bit to fit this larger diameter clevis and kingpin.

The center to center dimension doesn't change, regardless of which uniballs you decide to run, because we've already compensated for that with the height of the misalignments that we sell. You can cut the king pin down if you need a shorter center to center but you'll have to compensate with your bolt length and re-step the kingpin on a lathe. We sell two different upper king pins for this setup. 10-1/4" upper pin makes 14-7/16" on center and 11-1/4" upper pin makes 15-7/16" on center.

The top of the kingpin is stepped and requires a certain misalignment that indexes onto that step. Part number HMA15034KTKWS for the standard uniball or part number TTHMA15034PRM for the taller TT uniball.

That is why we've provided you with the 7-5/8" or 8-5/8" dimension (see diagrams below) from the edge of the nut to the top edge of that stepped spacer. You'll take that 7-5/8" or 8-5/8" dimension and combine that with the height of your uppermost misalignment to figure out what upper bolt length you'll need.

Running TT uniballs you'll need per upright:

Obviously, if you're building two uprights, then double these quantities.

One 14 degree or 16 degree clevis

Part number CL6414D or CL6416D

One upper 10-1/4" or 11-1/4" king pin sleeve

Part number 64CPL or 64CPL11

One upper bolt (length depends on the very top misalignment you run)

One upper top misalignment spacer

Part number HMA15034TTRSH or HMA15034TTR

One stepped upper misalignment spacer (internal stepped for kingpin)

Part number TTHMA15034PRM

Two 3/4" Nylocs

Part number HARA21675

Two upright spacers

Part number KTKUPSP

One 9-1/2" lower bolt

Part number 3/4X912SB

Two lower misalignment spacers

Part number TTHMA15034PRMNS

One lower king pin sleeve

Part number 64CPS

One 12 bolt 2-1/2" hollow snout (check snout lengths for your brake hub two offsets available)

Part number LP2512BSL left or LP2512BSR right

Part number 2512BSPL left or 2512BSPR rightTwelve 3/8" 12 pt bolts for the snout

1"L part number 318112P for low pro snouts

1-1/4"L part number 31812512P for non LP snoutsTwo TT 1-1/2" bore uniballs

Part number WSSX24T or HCOM24ET8

One gusset kit (or make your own)

Part number 59SPGK (requires a lot of trimming)

Obviously, if you're building two uprights, then double these quantities.

Part number 2512BSPL left or 2512BSPR right

1-1/4"L part number 31812512P for non LP snouts

Running standard uniballs you'll need per upright:

Obviously, if you're building two uprights, then double these quantities.

One 14 degree or 16 degree clevis

Part number CL6414D or CL6416D

One upper 10-1/4" or 11-1/4" king pin sleeve

Part number 64CPL or 64CPL11

One upper bolt (length depends on the very top misalignment you run)

One upper top misalignment spacer

Part number HMA15034BH or HMA15034JPS or HMA15034PRM

One stepped upper misalignment spacer (internal stepped for kingpin)

Part number HMA15034KTKWS

Two 3/4" Nylocs

Part number HARA21675

Two upright spacers

Part number KTKUPSP

One 9-1/2" lower bolt

Part number 3/4X912SB

Two lower misalignment spacers

Part number HMA15034KTK

One lower king pin sleeve

Part number 64CPS

One 12 bolt 2-1/2" hollow snout (check snout lengths for your brake hub two offsets available)

Part number LP2512BSL left or LP2512BSR right

Part number 2512BSPL left or 2512BSPR rightTwelve 3/8" 12 pt bolts for the snout

1"L part number 318112P for low pro snouts

1-1/4"L part number 31812512P for non LP snoutsTwo standard 1-1/2" bore uniballs

Part number COMH24T or FKSH24T or HCOM24T or HCOM24TKH300

One gusset kit (or make your own)

Part number 59SPGK (requires a lot of trimming)

Obviously, if you're building two uprights, then double these quantities.

Part number 2512BSPL left or 2512BSPR right

1-1/4"L part number 31812512P for non LP snouts

10-1/4" Upper Pin = 14-7/16"

11-1/4" Upper Pin = 15-7/16"

In an ideal situation, the center point of the spindle's inclination will intersect the center point of the tire. This isn't always possible because of the backspace on your wheel and where the brake hub lands. Often times when you're building a vehicle, you won't already have the brakes, wheel and tire already in hand to fine tune exactly where everything will be.

If your front a-arms are already fabricated, you can draw an imaginary line from the upper uniball to the lower uniball. This will give you an idea of what spindle inclination your vehicle is setup for. Of course, on any vehicle you'll have adjustment points to adjust your camber which will affect what degree you come up with when measuring your inclination.

If your front a-arms are already fabricated, you can draw an imaginary line from the upper uniball to the lower uniball. This will give you an idea of what spindle inclination your vehicle is setup for. Of course, on any vehicle you'll have adjustment points to adjust your camber which will affect what degree you come up with when measuring your inclination.

Related Parts

PME Weld On Gusset Kit For Their 5-7/8" Diameter Billet Clevis Uprights - Does One Upright

In Stock

Price: $129.99

Kartek Off-Road Pinch Style Grand National Or 2-1/2" Hollow Spindle Left Hand Thread Spindle Nut

In Stock

Price: $115.00

17-4 Stainless Steel Misalignment Spacer For 1-1/2" Uniball For 3/4" Bolt 4" Stack Height

In Stock

Price: $41.99

FK Rod Ends 1-1/2" ID, 2-3/4" OD COMH24T PTFE Coated Uniball Spherical Bearings F1 Fit

In Stock

Price: $55.99

FK Rod Ends 1-1/2" ID, 2-3/4" OD COMH24T PTFE Coated Uniball Spherical Bearings F2 Fit

In Stock

Price: $55.99

FK Rod Ends 1-1/2" ID, 2-3/4" OD FKSH24T PTFE Coated Uniball Spherical Bearings F2 Fit

In Stock

Price: $114.99

FK Rod Ends Trophy Truck 1-1/2" ID, 2.917" OD WSSX24T Uniball Spherical Bearings

In Stock

Price: $349.99

Aurora Bearing Company Trophy Truck 1-1/2" ID, 2.917" OD HCOM-24ET-8 Uniball Spherical Bearings

In Stock

Price: $496.09